SPARE PARTS:

Availability of spare parts for the air circuit breaker or moulded-case type of apparatus is an essential condition for correct maintenance of every installation. To ensure maximum levels of assistance and to facilitate selection and ordering of the spare parts, products can offer you maximum long-term guarantees and covered by a warranty.

REPAIRS:

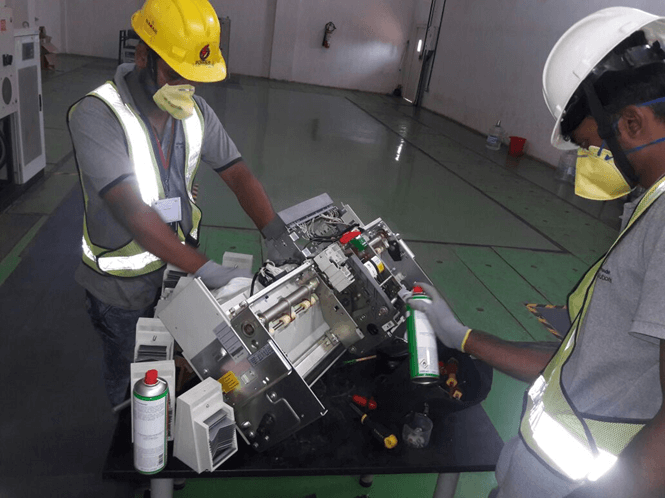

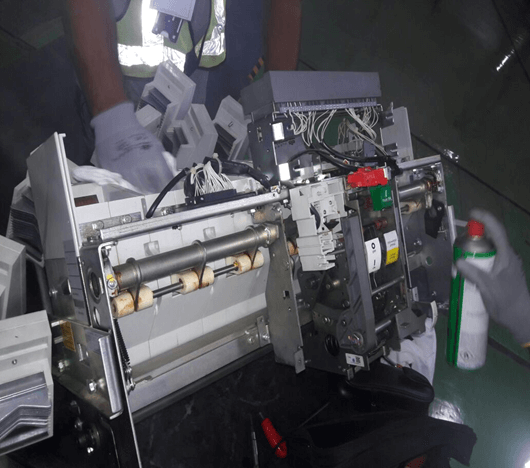

"When normal maintenance is no longer sufficient, a complete overhaul of the electrical apparatus must be carried out in order to solve problems specifically connected with a particularly long or heavy use of the apparatus. Overhauling, which must be carried out after very variable periods of time, according to the type of apparatus and the use it has been put to, consists of checking and reinstating the function of each electrical and mechanical part. Among other things, it also covers checking correct operation of the protections, to make sure and guarantee that the circuit breakers continue to trip in the foreseen ways and times.

Simply by sending them a Mobile indicating the type of apparatus and the problem encountered.

MAINTENANCE:

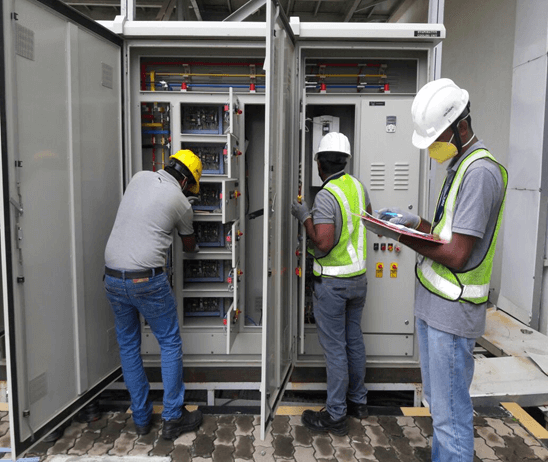

Our activity in preventive and scheduled maintenance consists of regular and predefined component replacements in order to reduce the risk of failure and increase the lifetime of the product, thus lowering the overall operational costs.

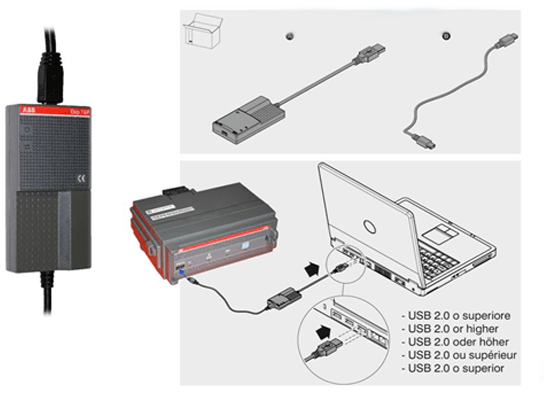

Our team is trained on adherence of safety work practices and gel with the customer safety instruction while at site. Our team is equipped with PPE’s, required tools and tackles, special test equipments like ACB microprocessor based relay test kits.

As a part of PM activity we carryout thermograph inspection of busbar joints, cable termination and equipment termination joints to identify hot spots and take corrective actions to eliminate equipment breakdown.

Specialised Support

We can undertake Service Support for Products normally used in Electrical Networks like Step-down Transformers, Isolation Transformers, Medium Voltage Circuit Breakers, Compact Secondary Substation, and Terminal Ring Main Units.

Assessment & Maintenance

We carryout, long term maintenance and improvement plan on products. The purpose of the assessment is to define measures to be taken for lowering operational costs, improving productivity, reducing environmental impact and enhancing safety. This is carried out by checking plans or technical documentation, checking of apparatus wear and tear conditions; anticipate as much as possible eventual corrective actions, checking the quantity of available spare parts, their warehousing conditions and suggesting any eventual re-integration. An effective maintenance plan not only helps customers plan and budget maintenance costs but also helps plan for future product upgrades, retrofits and replacements.

RETROFITTING:

"requirements. Problems relating to functionality, co-ordination and safety such as the need to improve electrical and mechanical performances, to enlarge the installation or to adapt it to standard- can ,in fact, require retrofitting or revamping operation, which are needed to replace inadequate or obsolete apparatus, or addition of new piece of apparatus to installation.

Routine maintenance operation does not always compleMobiley satisfy your Responds to your problem with a complete service. In fact the Technical Assistance

Works alongside the customer in a consultancy capacity and provides operative service. Any replacement of obsolete apparatus with ones of new design is carried out using special kits.

The Technical Assistance retrofitting offer covers the whole range of requirements you have, from the single component to the larger and complex installation.

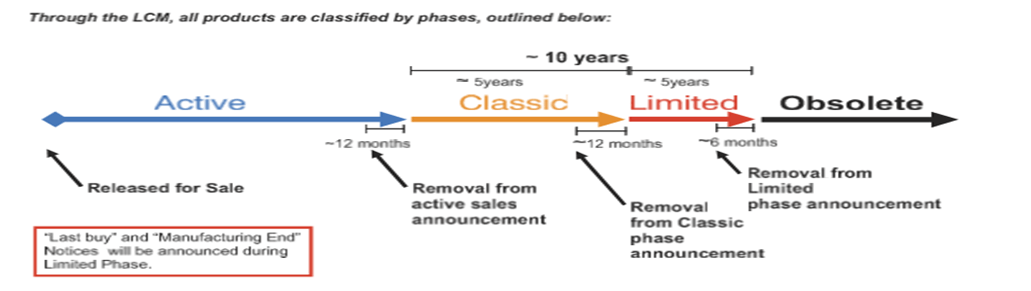

Benefits of Life Cycle Management:

Total transparency of products life cycle

- Commercial offer optimized management (warranty, pricing, deliveries. etc)

- Product residual life visibility (long term supply agreements, declarations etc)

Production management optimization:

- Production transition

- Availability of finished products, spare parts and retrofitting kits

- Production layout of material planning

Communication to the customer by Technical information:

FAULT PREVENTING AND THERMOGRAPHY:

The techniques for forecasting and therefore preventing fault in electrical apparatus have been characterised by rapid and significant developments.

When used constantly, diagnosis nowadays allows maintenance to be programmed in a targeted and economically advantageous manner, anticipating or delaying the interruption according to the management priority of installation.

Some controls, measurements and tests can be carried out directly on your installation, others in the laboratory. Thermography is one of the latest control techniques which make available to ensure correct operation of the electric installation.

TRAINING:

Training programs for engineers, programmers, maintenance and operations personnel provide up-to-date technical expertise for existing and new products, processes, and technology advances.

We help you to increase the skill level and knowledge of your employees through training assessment programs including competence development, custom courseware and coaching services.

Accurate training will increase your capability to respond rapidly and efficiently in any given situation hence improving operational efficiency of your assets.